About Us

Seamless Steel Pipe

The production of our seamless pipes is tightly regulated and all of the pipes we stock have been fully tested to international standards to ensure we only supply the highest quality products.

More details,please email us

Description

Package Information

Inquiry

| Product | Seamless Pipe,Seamless Carbon Steel Pipe,Carbon Steel Seamless Pipe,Hot Rolled Seamless Steel Pipe, Cold Drawn Seamless Steel Pipe, Cold Rolled Seamless Steel,Seamless Steel pipe & tube, black seamless steel pipe, SMLS Steel Pipe & Tube |

| Application | For converying gas, water & oil for Fluids Transmission,For High Temperature Service |

| Size | OD: 1/8" ~ 48" (10.3 ~ 1219mm) |

| WT: 1.25-70mm,SCH 10-160, SCH STD, SCH XS, SCH XXS | |

| LENGTH: Fixed Length (5.8/6/11.8/12mtr), SRL, DRL | |

| Standard | ASTM A106,Grade A/B/C,API 5L,JIS G3454,G3455,G3456,DIN1629/EN10216-1,EN 10208 |

| Ends | Square Ends/Plain Ends (straight cut, saw cut, torch cut), Beveled/Threaded Ends |

| Surface | Bare, Lightly Oiled, Black/Red/Yellow Painting, Zinc/Hot dip galvanized/Electro galvanized, Black,Varnish coating/Anti rust oil, Anti-corrosive Coatings (Coal Tar Epoxy,Fusion Bond Epoxy, 3PE) |

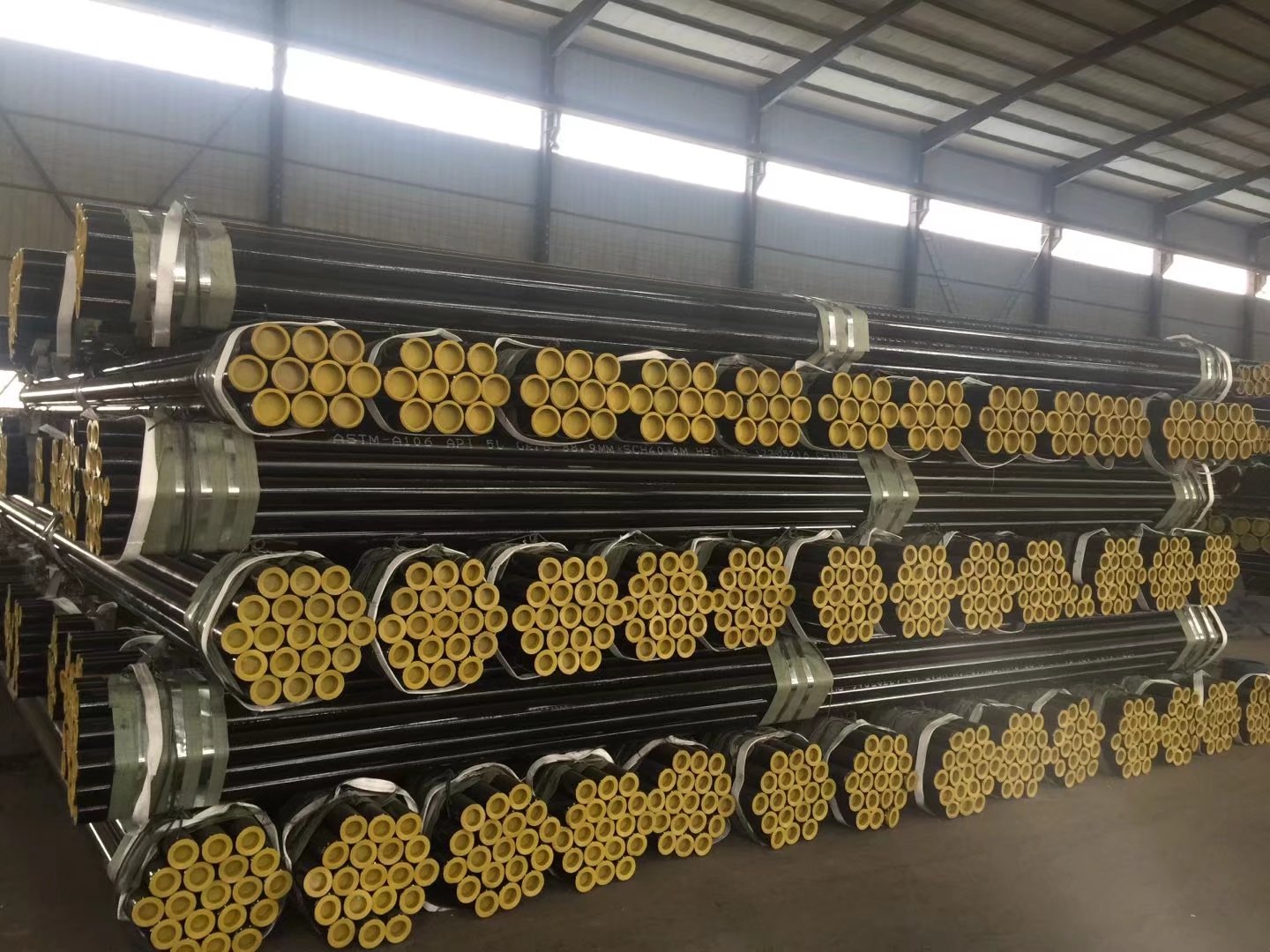

| Packing | Bundled/ln Bulk, Plastic Caps Plugged, Hexagonal bundles of max. 2,000kg with several steel strips, Two tags on each bundle, Waterproof Paper Wrapped, PVC sleeve, and sackcloth with several steel strips, Plastic caps. |

| Test | Chemical Component Analysis, Mechanical Properties (Ultimate tensile strength, Yield strength, Elongation), Technical Properties (Flattening Test, Bending Test, Hardness Test, Impact Test), Exterior Size Inspection, Hydrostatic Test, NDT TEST ( ET TEST, UT TEST) |

| More details | Delivery time and prices, please mail us:[email protected] |

| Packing |

| 1- Plastic caps plugged at the two sides of pipe ends |

| 2- Should be avoided by the steel strapping and transport damage |

| 3- Bundled signs should be uniform and consistent |

| 4- The same bundle(batch) of steel pipe should be came from the same furnace. |

| 5- The steel pipe has the same furnace number, the same steel grade, the same specifications. |